POWDER SPHEROIDIZATION

Powder spheroidization is the transformation of either agglomerated powders produced by spray drying and sintering techniques, or angular powders produced by conventional crushing methods, into spherical powder.

Induction plasma technology is used to achieve this through in-flight heating and melting of feed material particles followed by cooling and solidification under controlled conditions.

The spherucal powders can cater to a range of applications such as

hard surfacing, cold spray, thermal spray, metal injection molding

and additive manufacturing.

The key advantages of powder spheroidization are as follows:

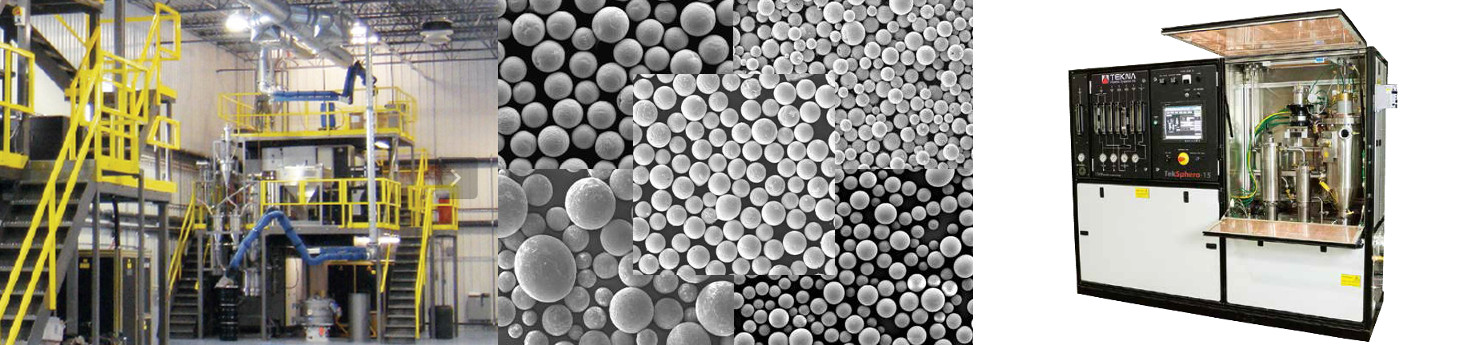

Aeromac Thermal provides a range of Tekna powder spheroidization equipment using their unique spheroidization process. We also offer a range of spherical powders manufactured by Tekna's powder spheroidization technology.

Tekna is a world leader in induction plasma technology, ensuring the highest level of quality and innovative equipment and powders.

POWDER SPHEROIDIZATION SYSTEMS

SPHERICAL POWDERS

Contact us

for technical data sheets, more information or any other enquiries.

The key advantages of powder spheroidization are as follows:

- Improves flowability

- Reduces internal porosity

- Higher packing density

- Less friable powder

- Increases purity

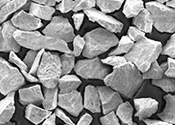

| PROPERTIES | BEFORE POWDER SPHEROIDIZATION | AFTER POWDER SPHEROIDIZATION |

| Photograph |  |

|

| Particles | WC (-100+400 Mesh/40-150um) | WC (-100+400 Mesh/40-150um) |

| Tap Density | 8.1 g/cm3 | 10.2g/cm3 |

| Hal Flow Test | 19sec/50g | 7sec/50g |

Aeromac Thermal provides a range of Tekna powder spheroidization equipment using their unique spheroidization process. We also offer a range of spherical powders manufactured by Tekna's powder spheroidization technology.

Tekna is a world leader in induction plasma technology, ensuring the highest level of quality and innovative equipment and powders.

POWDER SPHEROIDIZATION SYSTEMS

| EQUIPMENT | BRIEF | SPHEROIDIZABLE MATERIALS |

|

TekSphero-15 |

|

The

technology can spheroidize the following (not limited to)

Capacity of plasma treatment

|

|

TekSphero-40 |

|

|

| TekSphero-80 |

|

|

| TekSphero-200 |

|

|

| Custom Systems | We can work with you to help address specific requirements for customized equipment and turn key processes. |

SPHERICAL POWDERS

| SPHERICAL POWDER | BRIEF |

| Cast Tungsten Carbide (SCWC) | These powders are manufactured by Tekna's state-of-the-art powder spheroidization equipment. They are well-known for their superior quality and uniformity, and offer higher density, higher purity and better flow than standard powders. They are an excellent choice of precursor for applications requiring high quality materials. |

| Tungsten | |

| Titatium Carbide (TiC) | |

| Tantalum | |

| Molybdenum | |

| Silicon Dioxide | |

| Silicon | |

| Commercially Pure Titanium (CPTi) | |

| Titanium Aluminium Vanadium | |

| Custom Spherical Powders | We can work with you to help address specific requirements for customized materials and specifications (e.g. Alumina, Boron Carbide, Copper, Niobium Carbide, Vanadium Carbide etc) |