LASER CLADDING

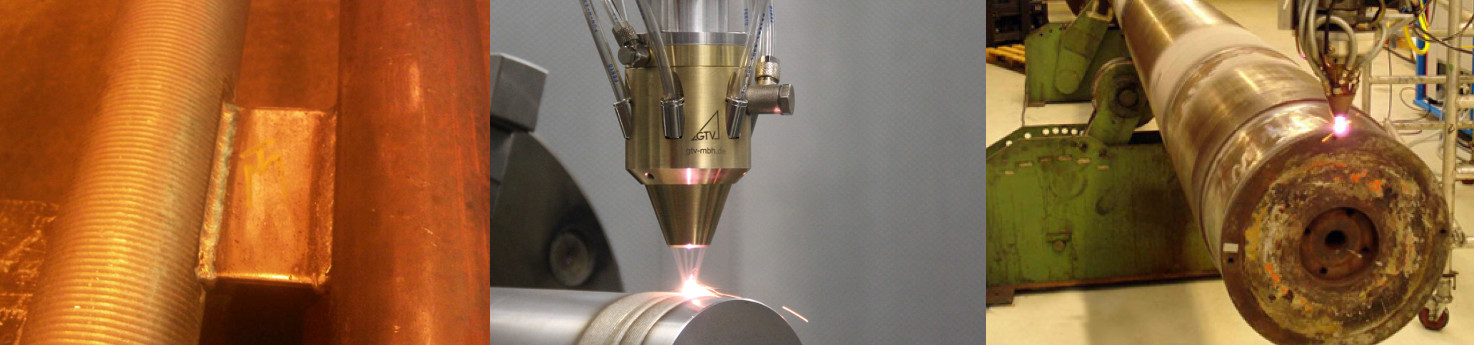

GTV's Laser Cladding systems have been successfully implemented laser clad coatings for a variety of applications e.g. gas turbine rotor coatings, valve ball coatings, internal diameter coatings, etc and mobile on-site laser clad repair coatings. These systems can be supplied on a turnkey basis complete with robotics, part manipulators, acoustic booth and dust collector, or on a modular basis.

Aeromac Thermal also supplies a range of Wall Colmonoy, USA laser cladding powder and wire alloys for the protection and renovation of critical industrial components.

LASER CLADDING EQUIPMENT

| EQUIPMENT | BRIEF |

| GTV Laser Cladding Turnkey Systems |

|

| GTV Laser Power Controller |

The GTV Laser Power Control system is designed for laser power control during the laser process. An intelligent camera directly records the laser spot of the laser welding through a coupling optics at the tip of the laser nozzle. The obtained image is evaluated in the camera using the LPC algorithm for image processing. The laser power is then apdapted to the process so that the melt pool characteristics are optimal with regard to the requested parameters. Four digital outputs of the camera are used for information transfer between the camera and the laser controller. The signals are detected by the laser unit and directly fed into the laser power control. The system is characterized by high reliability, ease of use and great flexibility both in hardware and in software. |

|

GTV "CladdOn" Compact Laser Control with Integrated Powder Feeder Unit

| The compact GTV laser control with integrated powder feed unit "CladdOn“ was developed for fast and efficient entry into laser cladding applications. The process visualization and control is carried out via a Siemens touch screen and a fold-out keyboard integrated in the front panel. This compact design is fully integrated as one unit on wheels allowing an unprecendented combination of mobility and operation. |

LASER CLADDING ALLOYS

| ALLOY | BRIEF | FORMS |

| COLMONOY® Nickel-based Alloys |

|

The laser clad alloys are supplied as 100-270 mesh size. Other sizes available upon request. Note: Colmonoy® 88 is available as powder or cored wire. |

| WALLEX™ Cobalt-based Alloys |

|

|

| GTV Laser Cladding Powder |

|

|

| Customer-specific Alloys | Many customers have applications which require specific alloys in order to achieve specific required coating properties. We can work with you to help address specific requirements. |

POWDER FEEDERS FOR LASER CLADDING

| POWDER FEEDER | BRIEF |

| GTV Powder Feeder Systems | The GTV PF

Series of Powder Feeders are an advancement of the PT Twin system which is in use for more than 30 years and has proven itself in the field of thermal spraying. In addition, the feeder is used frequently in laser technology including Laser Cladding and Laser Metal Deposition (LMD) based on its extreme feeding precision - even at low feed rates.

The special plate feeder principle with powder suction guarantees exact and precisely reproducible powder feed rates. The powder feed rate is linearly proportional to the plate speed. For all standard units, there are stand-alone versions, e.g. with own PLC and display. All relevant parameters (such as plate and stirrer speed) are set and displayed using the Siemens display (TP177) in the front of the console. Commands can also be entered via the monitor of the plasma/HVOF controller console. In addition, the standard powder feeder has an interface that can be addressed externally, for example, by a robot. Available powder feeder models include PF 2/1, PF 2/2, PF 3/3, PF 4/2, PF 4/3, PF 4/4, PF 1/1W, PF 2/2W, PF 3/3W, PF 2/1LC, PF 2/2LC Typical Specifications:

|

|

|